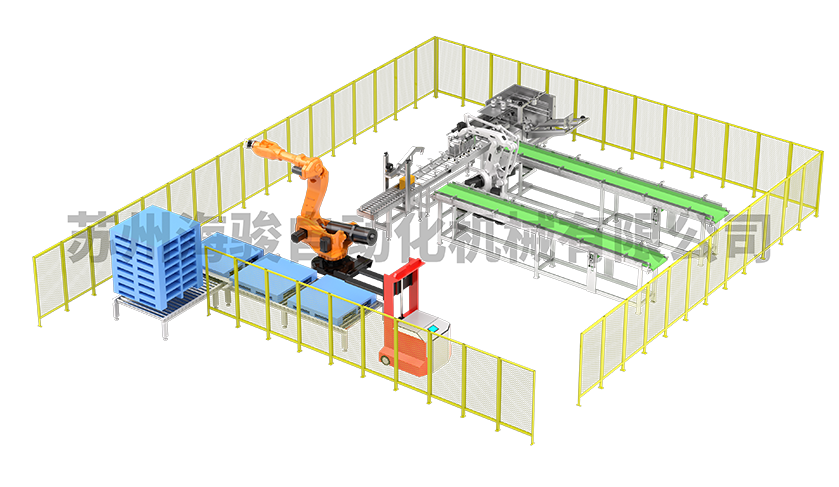

Robotic Packing, Strapping, Palletizing and Material Handling

subcategory:Robot Automatic Loading and Unloading

Robot automatic loading and unloading refers to the automated loading and unloading operations of workpieces between processing equipment (such as machine tools, injection molding machines, etc.) and material platforms through industrial robots, which is a key link in intelligent manufacturing production lines.

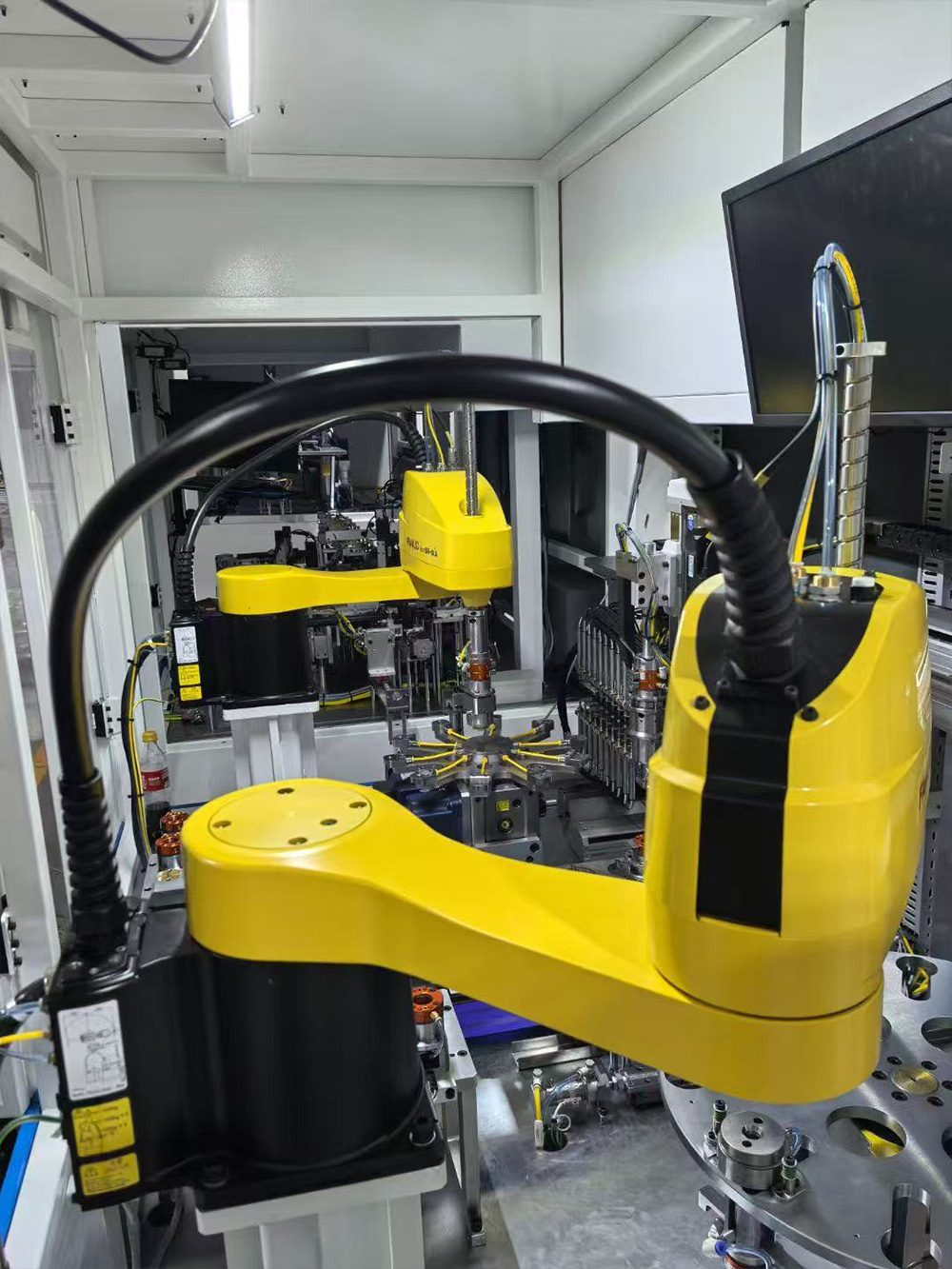

Robot automatic loading and unloading refers to the automated loading and unloading operations of workpieces between processing equipment (such as machine tools, injection molding machines, etc.) and material platforms through industrial robots, which is a key link in intelligent manufacturing production lines. The system is mainly composed of industrial robots, visual inspection systems, grabbing fixtures, material conveying lines, and control systems: The robot is equipped with special fixtures (such as vacuum suction cups, mechanical claws) to accurately grab workpieces. The visual system conducts real-time detection and correction of the position and posture of materials to ensure the accuracy of loading and unloading. The control system coordinates the action timing of the robot and processing equipment to achieve full-process automation.

Key advantages: Significant productivity gains with 24/7 operation and reduced manual intervention; lower labor intensity and human errors for improved consistency; flexible adaptation to multi-variant workpieces via tooling or program adjustments. Widely used in automotive, 3C electronics, and metalworking industries—especially in high-volume repetitive handling scenarios. With advancements in collaborative robots and AI, this technology is evolving toward high flexibility and intelligence, enabling deeper integration into production lines and driving manufacturing automation and digital transformation.

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou 0512-66510322

0512-66510322 0512-66510623

0512-66510623 15306205950 (WeChat same)

15306205950 (WeChat same) szhaijun06@163.com

szhaijun06@163.com