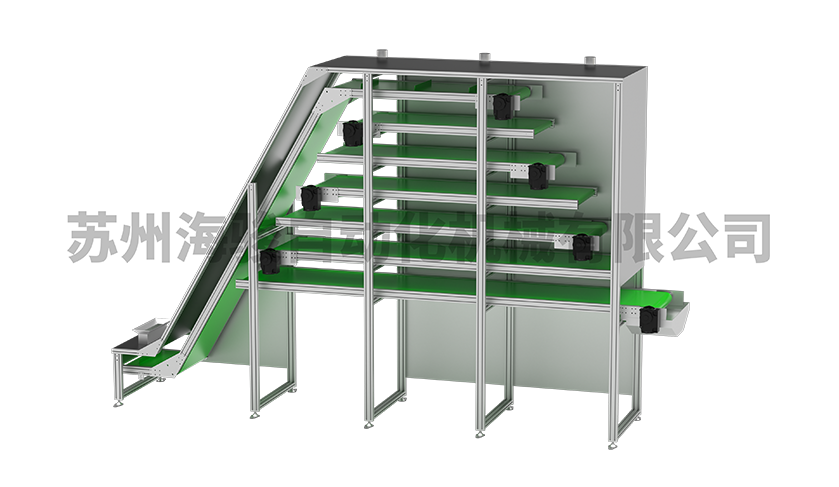

Multi-layer Belt Conveyor Line

subcategory:Conveyor line

A conveyor line is an automated system that enables directional material transport through continuous or intermittent motion, widely used in manufacturing, logistics, food, pharmaceuticals, and other industries. Its core components include drive units, transmission chains (or belts/rollers), support frames, and control systems.

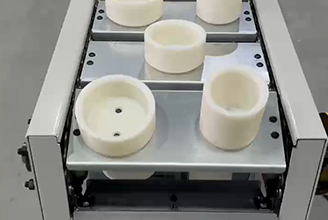

A conveyor line is an automated system that enables directional material transport through continuous or intermittent motion, widely used in manufacturing, logistics, food, pharmaceuticals, and other industries. Its core components include drive units, transmission chains (or belts/rollers), support frames, and control systems. It can be customized as belt conveyors, roller conveyors, chain-plate conveyors, or overhead conveyors based on material characteristics and application needs.

Key features include high efficiency, stability, and versatility: Motor-driven transmission achieves speeds ranging from meters to tens of meters per minute, significantly boosting material flow. It supports horizontal, inclined, or vertical transport, handling boxed, bulk, or small-item loads, with optional add-ons like baffles or side guards to prevent slippage.

In industrial settings, conveyor lines often integrate with processing equipment and inspection devices to form automated production lines (e.g., chassis conveyors in automotive assembly or PCB lines in electronics). In logistics, they facilitate warehouse sorting and parcel handling. With smart upgrades, advanced models incorporate sensors and intelligent controls for real-time material tracking, load monitoring, and speed adjustment, enhancing flexibility and reliability as a critical link in modern industrial workflows.

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou 0512-66510322

0512-66510322 0512-66510623

0512-66510623 15306205950 (WeChat same)

15306205950 (WeChat same) szhaijun06@163.com

szhaijun06@163.com